Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

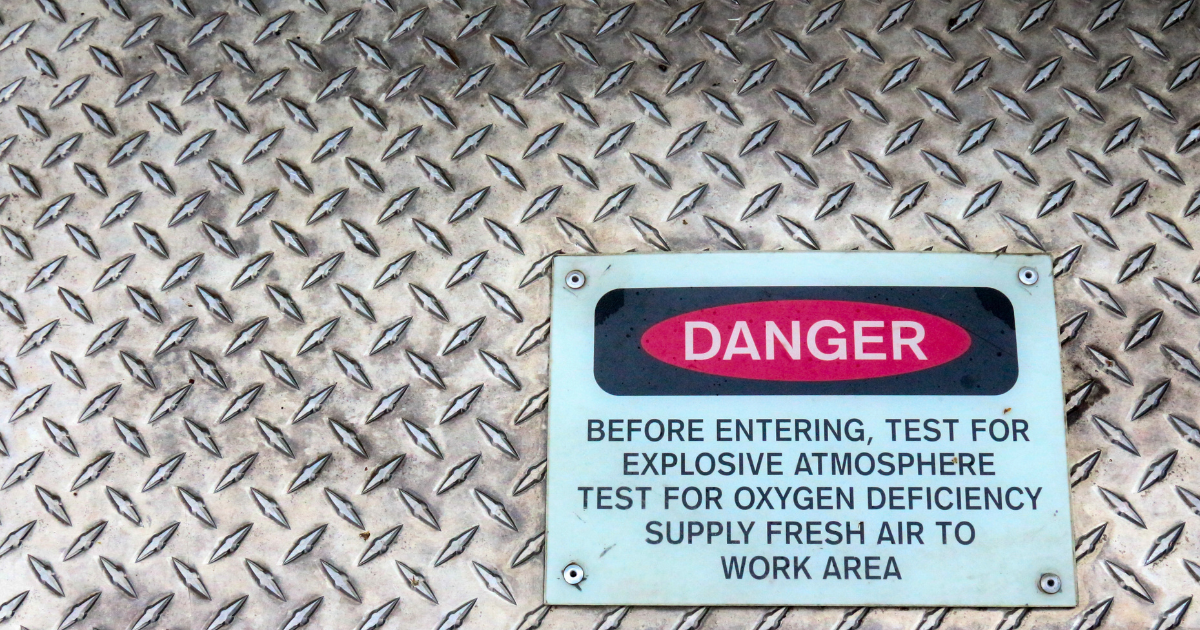

Confined spaces, whether in industrial settings or other work environments, present unique challenges that demand careful attention. This article delves into the critical aspect of managing confined space oxygen levels to ensure the safety and well-being of workers.

It’s important to check oxygen levels for several reasons.

It is essential to a sufficient supply of oxygen for human health. Monitoring is essential to preventing the risk of hypoxia, a condition where the body is deprived of enough oxygen and can have serious health consequences, in cramped areas or workplaces where oxygen levels can fluctuate.

Accidents are more likely to occur in settings where the oxygen concentration can fall below acceptable limits. Monitoring makes it possible to identify oxygen deficits early on and take prompt action to stop mishaps, injuries, or even fatalities.

Numerous laws about occupational safety and health require that oxygen levels be monitored in specific work settings, particularly small areas. Respecting these rules keeps companies safe from legal repercussions while also ensuring the welfare of their employees.

Keeping an eye on oxygen levels aids in spotting possible risks at work. Variations in oxygen concentration can be a sign of the presence of other chemicals or gases, bringing to light additional risks that must be taken into consideration in order to keep a safe working environment.

Prompt action is essential in the event of an oxygen level deviation. Early warnings from monitoring enable prompt emergency action. This entails starting the evacuation process, offering respiratory protection, and lessening the effects of unplanned events.

On the other hand, there might be a chance of oxygen enrichment in some industrial environments. By preventing circumstances in which oxygen levels rise above acceptable bounds, monitoring helps maintain a balanced environment and lessens the risk of fire.

Occupational Safety and Health Regulations:

Government agencies created the Occupational Safety and Health (OSH) regulations as a collection of guidelines and standards to protect the health, safety, and welfare of workers across a range of industries. These laws aim to prevent mishaps, illnesses, and injuries at work by addressing a variety of workplace dangers.

What defines a safe range of oxygen levels within confined spaces? In ambient air, the safe oxygen concentration for human health usually ranges from 19.5% to 23.5%. The amount of oxygen in the air that we breathe is represented by this percentage. Deviations from this range may have serious consequences for one’s health:

Below 19.5%: Hypoxia, a state in which the body and its tissues don’t get enough oxygen can be caused by low oxygen levels. Shortness of breath, disorientation, dizziness, and, in extreme situations, unconsciousness are possible symptoms.

Above 23.5%: While elevated oxygen concentrations are usually safe, they can present a fire risk. Oxygen-enriched environments greatly increase the chance of combustion, which increases the flammability of materials and the likelihood of fires.

Several factors can influence oxygen levels in confined spaces, and understanding these variables is crucial for ensuring a safe environment. Here are key factors that can affect oxygen levels in confined spaces:

Monitoring Tools and Equipment:

Various tools and equipment are utilized for monitoring oxygen levels in confined spaces. Here are some common use devices:

It is essential to select tools based on the requirement of the confined space and characteristics. Regular calibration, proper maintenance, and adherence to guidelines are essential.

Establishing robust SOPs is a cornerstone of effective safety management. A proper SOP includes pre-entry checks to continuous monitoring procedures, ensuring that organizations are well prepared to manage oxygen levels systematically. It includes:

Regularly following SOP is required for maintaining the safety of confined spaces.

Emergency Response Protocols:

Despite all preventive measures, emergencies can occur. Emergency response protocols are very essential in the event of oxygen level deviation. From evacuation procedures to communication strategy and first aid, a well-prepared response is essential for mitigating risk.

Training and Education for Personnel:

Knowledge is a powerful tool in the realm of workplace safety. It is important to give significant comprehensive training and education to the employees of any industry. By fostering awareness of confined space, risk, and nuances an oxygen level management organization can instill a culture of safety.

To sum up, this article provides a thorough overview of the challenging terrain of managing oxygen levels in confined spaces. Adhering to the principles delineated herein enables organizations to not only meet regulatory requirements but, even more crucially, cultivate a safety culture that safeguards the welfare of all employees.

References